Here’s something most flooring guides won’t tell you: the smaller your space, the more you can afford to spend per square foot. When I calculated materials for my 280 sq ft tiny house, I realized premium cork flooring would cost me $1,680 total. That same flooring in a 1,500 sq ft home? Nearly $9,000.

The best tiny house flooring options balance weight, durability, and aesthetics, with luxury vinyl plank (LVP), cork, and bamboo leading the pack for most small-space dwellers.

This changes everything about how you approach tiny house flooring. You’re not looking at budget constraints the same way someone with 2,000 square feet does. A $6-per-square-foot upgrade that seems extravagant in a typical home costs you maybe $200 more total.

What you’ll find here: seven flooring materials ranked by weight (crucial if you’re building on wheels), durability per dollar spent, and installation difficulty for DIY projects. I’ve included specific measurements and 2024 pricing because vague advice doesn’t help anyone planning a build.

Whether you’re working with a tiny house budget under $500 or willing to invest $2,000+ in flooring that’ll last decades, there’s an option that fits. I’ve also flagged which choices work for renters and which require permanent installation, because not everyone owns their tiny space.

What’s the Best Flooring for a Tiny House?

Luxury vinyl plank (LVP) ranks as the best overall tiny house flooring for most people. It weighs 2-4 lbs per square foot, costs $2-7 per square foot (about $400-$1,400 for 200 sq ft), handles moisture well, and installs easily over most subfloors with click-lock systems requiring no glue.

That said, “best” depends on your specific situation. Someone building a tiny house on wheels has different priorities than someone converting a backyard shed or renting a small apartment.

Three factors matter more in tiny spaces than traditional homes:

Weight per square foot. If you’re building on a trailer, every pound counts toward your towing capacity. The difference between tile (15 lbs/sq ft) and laminate (1.5 lbs/sq ft) across 200 square feet equals 2,700 pounds. That’s not trivial when you’re calculating trailer specifications.

Visual impact on perceived space. In 300 square feet, your floor is always visible. The wrong color or pattern can make tight quarters feel cramped. Light-toned floors with planks running lengthwise typically make narrow spaces feel longer.

Installation reversibility. Renters and folks who might sell need flooring that can be removed cleanly. Click-lock systems win here over glue-down or nailed options.

I learned this hierarchy the hard way. My first tiny house floor was gorgeous reclaimed oak, beautiful, yes, but 8 lbs per square foot. Combined with other material choices, I exceeded my trailer’s weight capacity by 400 lbs. Had to rip it out and start over with bamboo.

Flooring Options Ranked by Budget and Space

For spaces under 400 sq ft, flooring costs range from $200 (laminate at $1/sq ft) to $4,000+ (reclaimed hardwood at $20/sq ft). The sweet spot for most tiny house builds sits at $3-6 per square foot, giving you quality materials like LVP, cork, or bamboo for $600-$1,200 total.

Here’s how each option stacks up:

| Flooring Type | Cost/Sq Ft | Weight/Sq Ft | Durability | DIY Difficulty | Best For |

| Laminate | $1-5 | 1.5-2 lbs | 10-15 years | Easy | Budget builds, dry climates |

| Luxury Vinyl Plank | $2-7 | 2-4 lbs | 15-25 years | Easy | All-around use, moisture areas |

| Cork | $3-8 | 2-3 lbs | 20-30 years | Moderate | Insulation needs, standing comfort |

| Bamboo | $3-9 | 3-4 lbs | 25-30 years | Moderate | Eco-focus, modern aesthetic |

| Engineered Hardwood | $5-15 | 3-5 lbs | 30+ years | Moderate-Hard | Investment builds, classic look |

| Linoleum | $2-5 | 2-3 lbs | 20-40 years | Hard | Eco-priority, seamless look |

| Reclaimed Wood | $8-20 | 5-8 lbs | 40+ years | Hard | Character, sustainability story |

Budget tier breakdown for a 200 sq ft tiny house:

DIY Budget (Under $500): Laminate gives you the most coverage. Look at Pergo Outlast+ or TrafficMaster Lakeshore Pecan from Home Depot. These run $1.50-2.50 per square foot and click together without adhesive. Not ideal for bathrooms or kitchens where moisture accumulates, but solid for main living areas.

Mid-Range ($500-$2,000): This is where LVP and cork shine. LifeProof and COREtec offer waterproof LVP that handles bathroom spills and kitchen messes. Cork provides insulation value, important for heating and cooling efficiency in small spaces. Both materials cost $3-6 per square foot installed yourself.

Investment ($2,000+): Engineered hardwood or reclaimed wood. Yes, it’s more per square foot, but in a 200 sq ft space, you’re still under $4,000 for flooring that’ll outlast the structure. Carlisle Wide Plank offers stunning options, though you’ll want professional installation guidance.

Something I didn’t expect: cork flooring’s sound dampening made my tiny house feel less cramped. Footsteps echo differently, softer, less hollow. That acoustic quality improved daily life more than I anticipated.

Weight Considerations for Tiny Houses on Wheels

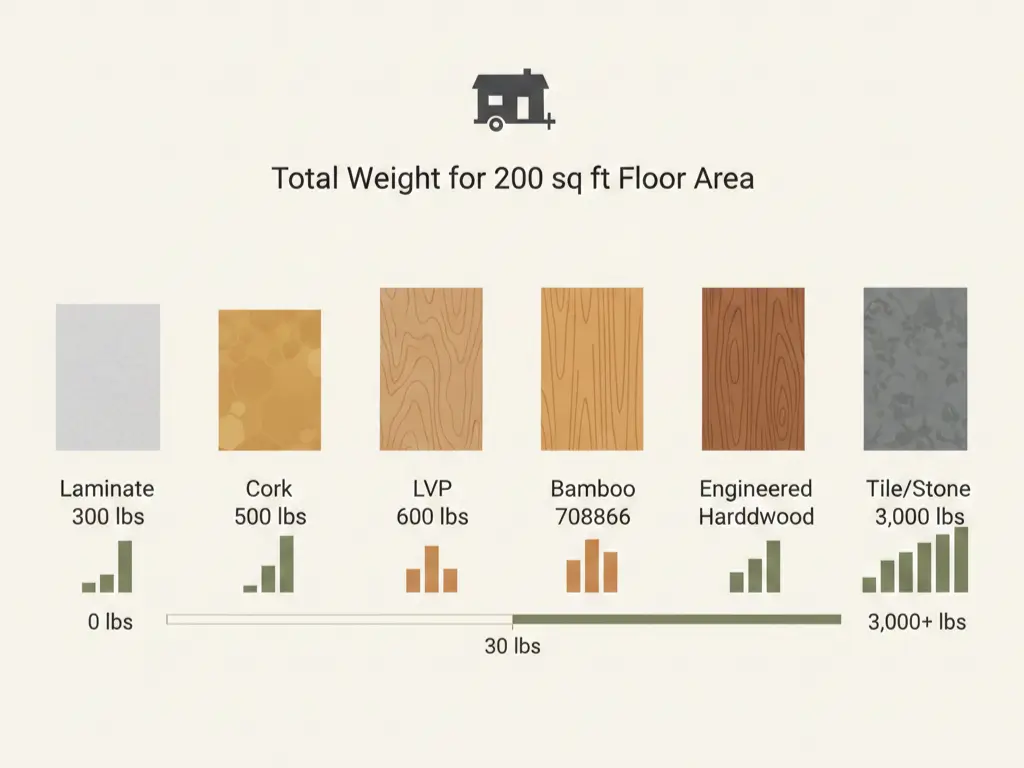

Tiny houses on wheels should aim for flooring under 4 lbs per square foot. At 200 sq ft of floor space, choosing laminate (300 lbs total) over tile (3,000 lbs total) saves 2,700 lbs, equivalent to adding a second bathroom’s worth of fixtures without weight penalty.

Weight math for tiny houses on wheels isn’t optional, it’s structural safety. Most trailers have Gross Vehicle Weight Ratings (GVWR) between 10,000-14,000 lbs. Your flooring choice eats directly into that capacity.

Here’s how flooring weight adds up in a 200 sq ft build:

| Flooring Type | Weight/Sq Ft | Total for 200 Sq Ft | Remaining Capacity Impact |

| Laminate | 1.5 lbs | 300 lbs | Minimal |

| LVP | 3 lbs | 600 lbs | Low |

| Cork | 2.5 lbs | 500 lbs | Low |

| Bamboo | 3.5 lbs | 700 lbs | Moderate |

| Engineered Hardwood | 4 lbs | 800 lbs | Moderate |

| Tile/Stone | 15 lbs | 3,000 lbs | Significant |

When I consult on tiny house builds, I tell people: don’t fall in love with tile unless you’re building on a foundation. Ceramic and stone look stunning but create cascading weight problems. You’ll need to cut weight elsewhere, thinner insulation, smaller kitchen fixtures, fewer built-ins.

The workaround? LVP products now convincingly mimic stone and tile patterns. LifeProof’s Slate tile-look vinyl weighs 2.8 lbs per square foot and handles water better than actual tile grout. My friend installed it in her 24-foot THOW bathroom, guests regularly ask if it’s real stone.

One exception: if you’re parking permanently and removing wheels, weight matters less. Some people overengineer foundations specifically so they can use heavier materials. Just know this locks in your location.

Installation Methods for Small Space Flooring

Click-lock floating floors require no adhesive, install in 4-8 hours for spaces under 400 sq ft, and allow renter-friendly removal. Glue-down and nail-down installations offer stability but require professional skills and prevent easy removal, crucial considerations for renters.

In small spaces, installation mistakes are more visible. There’s no furniture arrangement that hides a poorly cut corner when you can see every corner from any point in the room.

Three installation types:

Click-lock floating floors don’t attach to the subfloor. Planks snap together and rest on underlayment. This includes most LVP, laminate, and some engineered hardwoods. Benefits: fast installation, no specialized tools beyond a saw, completely removable. Downsides: can sound hollow without proper underlayment, slight movement underfoot.

Glue-down installation adheres flooring directly to subfloor. Common for sheet vinyl, linoleum, and some LVP. Benefits: stable, no hollow sound, good for moisture-prone areas. Downsides: permanent, requires adhesive expertise, difficult removal.

Nail-down installation applies to solid and engineered hardwoods. Benefits: most stable, traditional look, works with radiant heat. Downsides: requires skill, pneumatic tools, and proper subfloor, typically 3/4″ plywood minimum.

For DIY in tiny spaces, I recommend click-lock every time unless you have flooring experience. The margin for error is slim, and mistakes with glue or nails require starting over completely.

Subfloor requirements vary by tiny house type:

Standard tiny house on wheels: 3/4″ plywood subfloor is typical. Most click-lock products work directly on this with 2-3mm underlayment beneath. Check that your floor plan accounts for the added height, about 1/2″ total, when planning loft headroom.

Converted shed or container: May need subfloor leveling. Self-leveling compound costs about $30 per 50-lb bag and covers 50 sq ft. Worth the investment for a smooth result.

Rented small apartment: Skip anything requiring adhesive. Stick with high-quality click-lock LVP over existing flooring. Products like COREtec work over tile, concrete, and most existing floors as long as they’re level within 3/16″ over 10 feet.

Flooring Patterns That Make Tiny Spaces Look Bigger

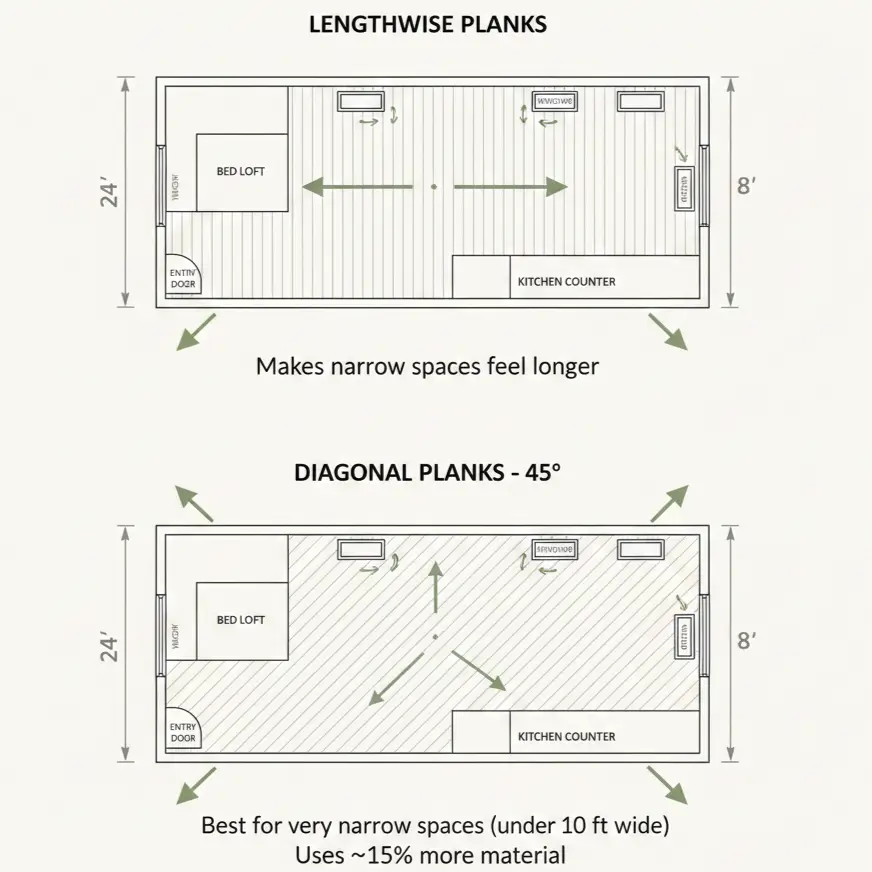

Plank direction, width, and color impact perceived space dramatically. Running planks parallel to the longest wall makes rooms feel longer. Wider planks (7-9 inches) with fewer seams create visual continuity. Light colors with LRV above 50 reflect more light, amplifying the effect of your lighting solutions.

I’ve seen the same 300 sq ft floor plan feel entirely different based solely on flooring choices. These visual tricks cost nothing extra but require planning.

Plank direction matters most. In my 24-foot tiny house (8 feet wide), running 6-inch planks lengthwise made the space feel like a hallway. Switching to diagonal installation at 45 degrees added visual width, the eye follows the longest line available. This used about 15% more material due to cuts but transformed the feel.

The general rule: run planks parallel to incoming light from windows and doors. This enhances the natural light path and makes seams less visible.

Plank width affects seam count. In 200 sq ft, 3-inch planks create roughly 67 linear feet of visible seams. 8-inch planks cut that to 25 linear feet. Fewer seams = smoother visual flow = larger perceived space. This aligns with minimalist design principles that work well in compact homes.

Color and Light Reflectance Value (LRV). This measurement tells you how much light a surface reflects, 0 is pure black, 100 is pure white. For tiny spaces, aim for flooring with LRV above 50.

| Flooring Color | Typical LRV | Space Effect |

| Whitewashed oak | 65-75 | Maximum brightness, shows dirt |

| Natural maple | 55-65 | Bright, warm, versatile |

| Light gray LVP | 45-55 | Modern, hides dust well |

| Medium brown walnut | 25-35 | Cozy but absorbs light |

| Dark espresso | 10-20 | Dramatic but shrinks space |

That said, I’ve seen dark floors work beautifully when paired with light wall colors and adequate lighting. The contrast can feel sophisticated rather than cramped. Just compensate with brighter walls and strategic window placement.

Eco-Friendly Flooring Choices for Sustainable Tiny Living

Cork, bamboo, linoleum (true linoleum, not vinyl), and reclaimed wood offer the strongest sustainability profiles. Cork and bamboo regenerate faster than traditional hardwoods, cork bark regrows in 9 years, bamboo in 3-5 years. Reclaimed wood prevents old-growth timber from entering landfills.

Many tiny house dwellers choose this lifestyle for sustainability reasons. Your flooring can align with those values without sacrificing aesthetics or durability.

Cork flooring comes from bark harvested without killing cork oak trees. Portugal produces most of the world’s cork, and responsible harvesting has sustained these forests for centuries. Beyond sustainability, cork offers thermal insulation (R-value of 1.125 per inch) and cushioned comfort for standing. Products from Amorim and ICork run $4-8 per square foot.

Bamboo technically isn’t wood, it’s grass. It reaches maturity in 3-5 years versus 40-60 years for oak. Cali Bamboo and MOSO offer FSC-certified options. Strand-woven bamboo (the most durable type) rates harder than oak on the Janka scale. Expect $4-9 per square foot.

True linoleum (brands like Forbo Marmoleum) contains linseed oil, cork, wood flour, and natural pigments. It’s been manufactured since the 1860s and biodegrades fully. Don’t confuse it with vinyl, they’re completely different materials. Linoleum costs $3-5 per square foot but requires professional installation.

Reclaimed wood gives character no new product can replicate. Nail holes, saw marks, and patina tell stories. Sources include old barns, factories, and gymnasium floors. Prices vary wildly, $8-20 per square foot, but for 200 sq ft, even premium reclaimed stays under $4,000 total.

The eco-consideration most people miss: transport. A locally-produced laminate may have lower total carbon footprint than bamboo shipped from China. If sustainability drives your choice, factor in shipping distance alongside material origin.

Making Your Final Flooring Decision

Choosing tiny house flooring isn’t about finding a universally “best” option. It’s about matching material properties to your specific constraints: weight limits, moisture exposure, budget, and aesthetic preferences.

Measure your space precisely and calculate total square footage. This number drives every decision. A 180 sq ft floor versus 320 sq ft floor changes what’s affordable in every budget tier.

Visit a flooring showroom and get physical samples of your top three choices. Live with them for a week. See how they look in morning versus evening light. Test them with water drops if moisture matters. Samples cost nothing and prevent expensive regrets.

If you’re building on a trailer and approaching weight limits, or if your subfloor needs leveling, consult a professional before purchasing materials. The cost of expert advice is cheaper than removing and replacing a failed floor.

Your floor touches every moment of tiny house life, morning coffee, working from home, relaxing after dinner. It’s worth getting right. For more guidance on creating cohesive small spaces, explore Veniola’s complete tiny house design resources.